The Ultimate Guide to Extending Life Expectancy: Undercarriage Parts Maintenance Made Easy

The Ultimate Guide to Extending Life Expectancy: Undercarriage Parts Maintenance Made Easy

Blog Article

Maximize Efficiency With Long Lasting Undercarriage Components

In the realm of heavy equipment and equipment, the function of undercarriage components is vital in making certain optimal performance and long life. The effectiveness and efficiency of these components can dramatically affect the total operation of machinery, making the option of sturdy undercarriage components a vital choice for drivers and managers alike.

Benefits of Making Use Of Durable Undercarriage Components

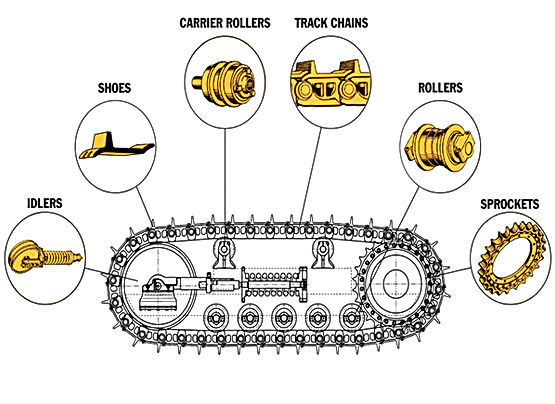

Using durable undercarriage components not only enhances the longevity of heavy equipment yet also decreases upkeep prices considerably. By spending in top notch undercarriage elements, such as tracks, sprockets, idlers, and rollers, equipment drivers can experience enhanced uptime and boosted general performance.

In addition, the longevity of heavy machinery is straight connected to the high quality of its undercarriage parts. Resilient parts can hold up against the rigors of requiring applications, making certain that the tools stays operational for prolonged durations. As an outcome, operators can avoid expensive downtime and maintenance expenses, ultimately taking full advantage of the return on financial investment for their equipment.

Factors Influencing Undercarriage Toughness

The durability of undercarriage components in hefty machinery is affected by various essential factors that directly influence performance and long life. One of the essential factors impacting undercarriage longevity is the high quality of products made use of in production. Premium products, such as hardened steel, are crucial for holding up against the severe conditions and heavy tons that undercarriage parts undergo. Appropriate upkeep techniques also play an important duty in figuring out the life-span of undercarriage components. Normal inspections, lubrication, and timely substitute of damaged parts can significantly expand the sturdiness of the undercarriage.

In addition, environmental variables can have a substantial effect on the longevity of undercarriage parts. Exposure to unpleasant products, extreme temperatures, and severe working conditions can increase deterioration on undercarriage components. Consequently, selecting undercarriage components that are specifically created to endure these ecological difficulties is crucial for guaranteeing sturdiness.

Additionally, the design and engineering of undercarriage parts have a direct influence on their toughness. Components that are made to disperse loads equally, lower friction, and reduce anxiety concentrations are extra likely to have a much longer lifespan - undercarriage parts. By considering these essential elements, devices drivers can maximize the sturdiness and efficiency of their undercarriage elements

Maintenance Tips for Prolonging Undercarriage Life

Carrying out routine maintenance routines is essential for extending the life expectancy of undercarriage parts in hefty machinery. Furthermore, guarantee that the undercarriage is effectively lubricated according to maker guidelines to decrease rubbing and stop premature wear.

Another essential maintenance tip is to maintain the undercarriage clean from dust, rocks, and debris. Accumulation in the undercarriage can speed up wear and corrosion, causing costly fixings. Washing the undercarriage after operation in severe conditions is recommended to stop these problems.

Finally, monitoring and recording maintenance activities can aid in creating a proactive maintenance schedule. Maintaining thorough documents of inspections, repair services, and replacements can provide useful understandings into the undercarriage's problem and performance gradually, aiding in predicting and protecting against possible failures. By adhering to these maintenance suggestions carefully, drivers can significantly boost the toughness and efficiency of undercarriage parts in hefty machinery.

Picking the Right Undercarriage Components

Selecting ideal undercarriage components is important for maximizing the performance and longevity of heavy machinery. There are numerous aspects to think about when it comes to selecting the appropriate undercarriage components. One vital aspect is comprehending the details needs of the device and the environment in which it will operate. Different applications may ask for different types of undercarriage elements, such as tracks, rollers, idlers, and gears. It is important to choose elements that are made to endure the certain Our site conditions the device will experience, whether it be harsh terrain, abrasive materials, or extreme temperatures.

Opting for respectable brands known for creating sturdy and high-performance undercarriage components can substantially impact the overall efficiency and long life of the machinery. By meticulously selecting the ideal undercarriage components, devices proprietors can enhance efficiency, decrease downtime, and prolong the life-span of their heavy machinery.

Study: Enhanced Performance With Long Lasting Components

Including resilient undercarriage components has actually demonstrated substantial improvements in equipment performance. One case research involved a construction company that upgraded its excavator's undercarriage elements to more resilient alternatives. The firm observed a remarkable decrease in downtime due to undercarriage maintenance, leading to increased efficiency and cost savings. The long lasting parts endured rough working conditions, decreasing damage considerably.

In another instance, a mining procedure replaced the undercarriage parts of its bulldozer with high-quality, resilient choices. This switch resulted in an exceptional enhancement in the excavator's ability to move and overall efficiency. The machine could browse tough terrains more efficiently, resulting in enhanced operational efficiency and decreased gas usage.

Additionally, a logging firm invested in sturdy undercarriage components for its forestry equipment. These situation studies emphasize the concrete benefits of utilizing resilient undercarriage components in enhancing equipment performance and durability.

Verdict

To conclude, making use of long lasting undercarriage components can dramatically boost performance and long life of heavy equipment. Factors such as correct upkeep and picking the ideal parts play a crucial role in taking full advantage of undercarriage toughness. By implementing these techniques, organizations can lower downtime, boost performance, and eventually save money on functional costs. Study have actually revealed that purchasing durable undercarriage parts can cause enhanced general efficiency and efficiency in various sectors.

The performance and efficiency of these parts can considerably affect the redirected here overall operation of machinery, making the choice of durable undercarriage parts a crucial decision for operators and supervisors alike.Incorporating long lasting undercarriage parts has shown substantial enhancements in equipment efficiency. These situation research browse around here studies emphasize the concrete benefits of making use of resilient undercarriage parts in enhancing machinery performance and longevity.

In verdict, making use of sturdy undercarriage components can considerably improve efficiency and durability of hefty equipment (undercarriage parts). Instance research studies have actually revealed that spending in sturdy undercarriage parts can lead to boosted overall performance and efficiency in various sectors

Report this page